Welcome to ELMO RIETSCHLE

Welcome to ELMO RIETSCHLE

Our wide range of Blower and Vacuum technologies will support all your demands and requests for vacuum and pressure.

Our wide range of Blower and Vacuum technologies will support all your demands and requests for vacuum and pressure.

Liquid Ring Vacuum Pump

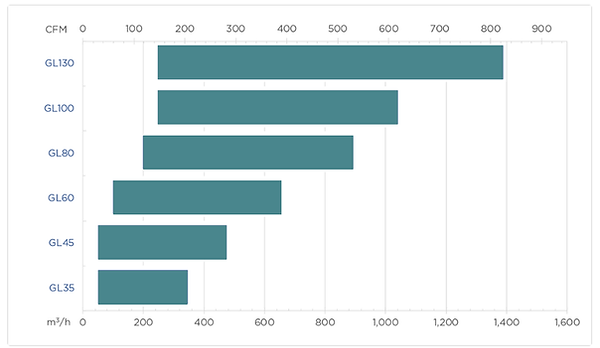

Medium Capacity, Vectra GL

Capacity 30 to 830 ACFM (50 to 1,400 m3/h)

The NASH Vectra liquid ring vacuum pump and compressor series delivers optimum performance with unprecedented production efficiencies. The Vectra GL models, with capacity ranging from 30 to 830 ACFM (50 to 1,400 m3/h), are engineered to deliver outstanding reliability and performance for general industrial applications.

Model

Download Brochure

Reliable and Efficient with Proven Performance

Based on proven reliable NASH conical liquid ring pump designs, the Vectra series delivers superior performance and reliability through several engineering upgrades.

-

Built-in mechanical seals eliminate shaft leakage

-

Improved cone angles, which decrease the size of the pump,

-

Patented Gas Scavenging Technology dramatically improves pump performance at high vacuum levels

Easy to Maintain - Low Total Cost of Ownership

The Vectra GL pump was engineered to be easy to maintain, with improvements that optimize performance and reliability.

-

Bearings placed outboard where they can be accessed without disassembly of the pump.

-

Pump body is engineered to reduce forces on the pump shaft

-

Lobe purges reduce erosion wear

Operates as a vacuum pump and compressor with a discharge pressure range of 29 psia (2 bar abs.)

Some applications require vacuum and compression in one process. Instead of handling the gas with two separate machines, our liquid ring vacuum pump and compressor models can do the job with only one pump - reducing cost and simplifying installation.

Reliable and Efficient with Conical Porting and Rotor Configuration

Patented in 1932, Nash’s variable conical porting design allows the force of compression to counter the weight of the rotor and shaft to help minimize load on bearings during operation. The variable porting optimizes pump performance across the entire operating range. With constant innovation, Nash’s patented design features:

-

Option for lobe purge to minimize damage from erosion in duties with solids present

-

Large differential pressure capability

-

Gas scavenging feature minimizes slip of gas from discharge to inlet improving capacity, especially at deep vacuum

-

High liquid carryover tolerance

-

Side discharge to minimize chance of flooded start

-

Self-priming design may allow elimination of booster pump in recirculated systems

Factory Service

Strategically located to provide support where and when you need it.

Parts

Built to our legendary standards using current designs and specifications. Fit and performance guaranteed.

Field Service

Our team of NASH Certified Technicians are available to supplement your in-house maintenance operations.

Technical Data

-

Suction Capacity: 30 to 830 ACFM (50 to 1,400 m3/h)

-

Vacuum Range: to 1 inHgA (to 33 mbar abs.)

-

Discharge Pressure Range: 29 psia (2 bar abs.)

-

Differential Pressure: to 14.5 psi (to 1 bar abs.)

-

Shaft Seals: Mechanical Seals single acting

-

Materials of Construction: Ductile Iron